News

Pirelli Silica from Rice Husk

02 Feb,2021

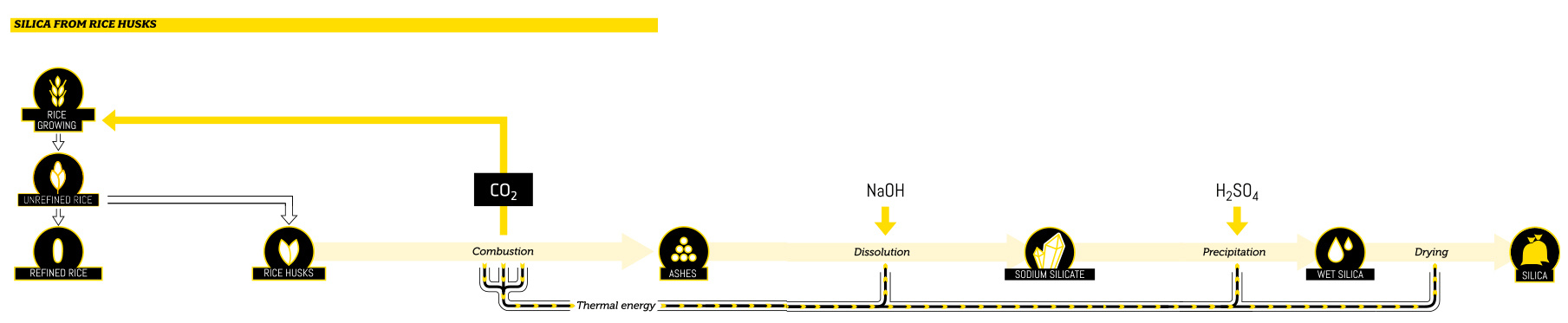

SILICA FROM RICE HUSKS

Silica is used in tyres to reduce rolling resistance, improving vehicle efficiency without reducing its road hold, especially under wet conditions. In its research on ever-more sustainable materials, Pirelli has concentrated on this raw material by seeking an alternative source for traditional processing methods.

The Group has developed a process at its plant in Santa Catarina, a renowned rice producing centre in southern Brazil, which can extract silica from rice husks. Rice husks are the external shell of the rice grain. Rice husks account for 20% of the weight of raw rice, and represent the principal scrap material of rice processing. Given the volume of global rice production, rice husks are available in huge quantities in many areas of the world. Rice husks already have many applications that are more or less sophisticated: from bedding for livestock to organic fertilizer, to solid fuel for electric power generation. In fact, rice husks have a significant energy content, amounting to 14 MJ/ kg. However, it is not yet appreciated in less developed areas of the world, and is burned in the field without exploiting its potential.

Aside from its interesting level of energy content, rice husks have another exploitable property, represented by its high silica content, which accounts for about 18% of its weight. In the traditional process, silica is made with a chemical process where crystalline silica, typically sand, is dissolved in a solution of water and caustic soda (NaOH). The result of this first step in the process is sodium silicate. Then an acid is added (typically sulphuric acid) to obtain silica precipitate as the principal product and sodium sulphate as the by-product. The reaction of crystalline silica with caustic soda requires a huge amount of thermal energy. But when rice husks are burned, the resulting ash is composed of non-crystalline silica that has a maximum residual carbon content of 8%. Compared with crystalline silica, this silica requires much less energy in the initial reaction. It is easy to imagine that this biomass may thus constitute an ideal raw material for the production of silica precipitate. All the thermal energy necessary for production can be generated if the rice husks are burned in the right way, and, at the same time, the non-crystalline silica reacts at far lower temperatures than in the traditional method.

Since the production process is thermally self-sufficient, the production of silica from rice husks not only allows energy recovery but also a significant reduction in CO2 emissions, precisely because all the necessary thermal energy is derived from the combustion of renewable biomass. This processing activity has been included in the research project being conducted in collaboration with the Italian Environment Ministry.

More information about this project may be found in the section “Relations with Institutions and Public Administrations”, in the Social Dimension chapter of this Report. Initial analyses show that this process offers a great advantage in terms of carbon footprint. Pirelli silica made from rice husks can reduce the carbon footprint by over 90% as compared with silica made with traditional processing techniques.

The production of silica from rice husks by Pirelli stands as a clear example of how innovations in the area of materials can be totally sustainable, contributing both to the exploitation of by-products that would otherwise be only partially reused, and the eco-sustainability of production processes. All of these benefits are accompanied by economic advantages that can be immediately related to the efficiency of the process.

This project was also reported in one of the most prestigious newspapers in the world, The Economist, at the beginning of 2013. In an article dedicated to Pirelli, this periodical mentioned the environmental benefits resulting from use of a substance obtained from renewable sources. Pirelli has set itself the target of extending the use of silica obtained from rice husks to premium tyres by 2017.

Previous article

Evosil Attends the 2020 Straw Comprehensive Utilization Expo

Next article

Related News

Rice husk white carbon black: Opportunities and Innovations from Rice By-products