News

Green and Sustainable Development: Market Status and Future Development Trends of Rice Husk Silicon Dioxide Industry

23 Jul,2024

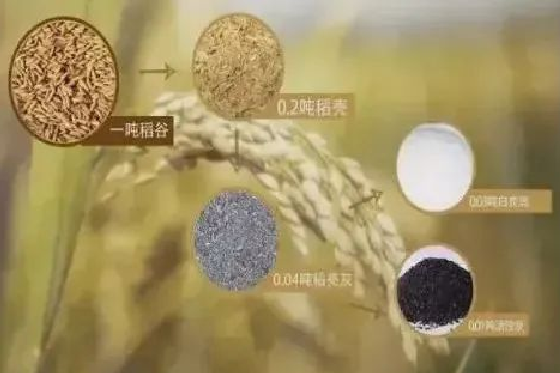

Rice husk ash silica, also known as biobased silica, is a material prepared from rice husk ash as raw material, and its main component is silicon dioxide (SiO2). Rice husk ash is a byproduct produced during the rice processing of rice husks. After treatment and calcination, the silicon content in it can be concentrated, extracted, and utilized.

China's rice production ranks first in the world, and rice is also the largest grain variety in China, with an annual output of about 200 million tons. Two thirds of the country's population relies on rice as their staple food. However, for a long time, China's rice processing has been at the primary processing level, with low levels of deep processing and comprehensive recycling. Rice husk by-products, which account for 20% of rice, have not been developed and utilized. The green development model of circular economy is not only an inevitable choice in the current global situation of population growth, resource scarcity, and ecological degradation, but also a necessary path for long-term harmonious coexistence between humanity and nature in the future.

Rice husk white carbon black is based on the green development model of circular economy in rice processing. It uses rice husk, a by-product of traditional rice processing, for combustion and power generation. The main component of silica in the obtained rice husk ash is extracted to produce white carbon black products. Compared with traditional quartz sand as the raw material for silica extraction, rice husk ash extraction is more environmentally friendly and green; At the same time, quartz sand is a non renewable mineral resource of silicon. With the development of industry, the excessive consumption of silicon resources has caused a certain degree of resource shortage. The renewable plant silicon extracted from rice husks not only solves the environmental pollution problem of rice processing waste, but also provides renewable silicon resources for industrial development, which has significant economic and social value.

Meanwhile, rice husk ash silica has small particle size and high specific surface area, making it play an important role in various fields such as rubber, coatings, feed additives, etc. Its characteristics include high wear resistance, chemical stability, and low coefficient of thermal expansion, making it a green and sustainable alternative to other materials.

Analysis of Market Driving Factors

With the development of modern science and technology, the demand for high-purity silica is increasing day by day. According to statistics, the silica content in rice husks is as high as about 20%, and China's annual production of rice husks is about 40 million tons, ranking first in the world. Rice husk ash is an agricultural byproduct, and its utilization helps reduce waste, which is in line with the trends of sustainable development and environmental protection. Rice husk ash, as an agricultural byproduct, has a relatively low acquisition cost, which helps to reduce raw material costs. But now the production systems of various countries are not fully mature, and for large-scale production, production costs are still at a high level. With the progress of technology and innovation, rice husk ash silica may play a huge role in new application fields, creating new market opportunities.

Market Status Analysis and Development Trend Prediction

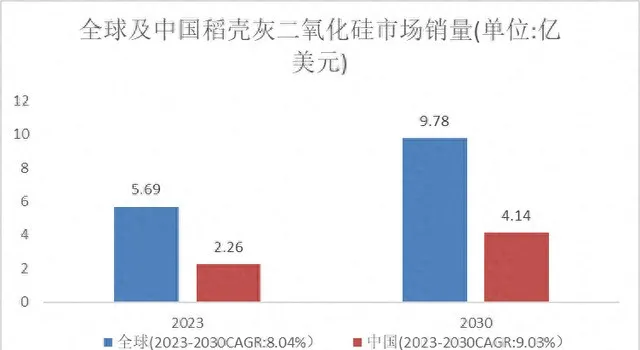

According to the research and statistics of the Hundred Suggestions Strategy, the total output value of the global rice husk ash silica market will reach 569 million US dollars in 2023, and is expected to reach 978 million US dollars in 2030, with a compound annual growth rate (CAGR) of 8.04% from 2023 to 2030. At present, the United States is still the largest producer of rice husk ash silica, with a total output value of 239 million US dollars in 2023. China, as the second largest producer, is developing rapidly, with a total output value of 226 million US dollars in 2023. It is expected that the output value will reach 414 million US dollars before 2030, with a compound annual growth rate (CAGR) of 9.03% from 2023 to 2030. In terms of production capacity and output value, it is comprehensively ahead of other regions in the world. From the perspective of the consumer end, the Asia Pacific region is currently the largest consumer end, with sales reaching 123114 tons in 2023. Among them, the sales in the Chinese market account for about 74% of the Asia Pacific market, with sales of 91245 tons. Next is the North American region, with a sales volume of 92128 tons in 2023.

Source: Research and compilation by DIResearch, 2023

Segmented market and downstream application analysis

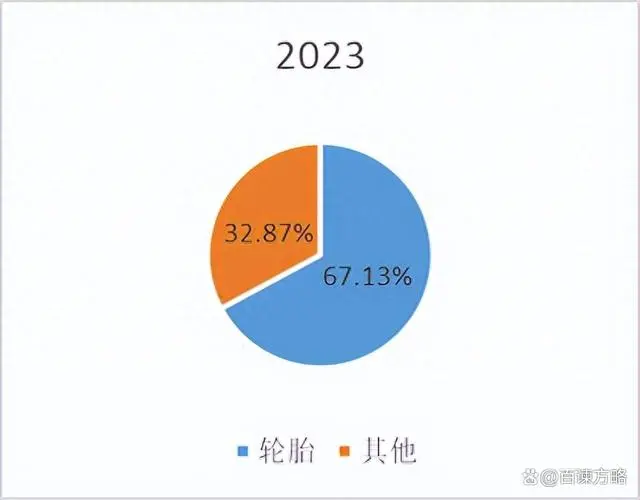

The main types of rice husk ash silica are high dispersibility and low dispersibility, with high dispersibility silica occupying the main market position. Highly dispersed silica is widely used in the crucial application of rubber reinforcement. As tire manufacturers continue to rely on highly dispersed silica to bring high-quality and innovative tires to the global market, the demand for highly dispersed silica is rapidly increasing. From the perspective of downstream applications, the demand prospects for rice husk ash silica in various fields such as green tires, toothpaste, coatings, silicone rubber, and animal feed additives are promising. Among them, the application of rice husk ash silica in tires accounts for the largest proportion, with a scale of 382 million US dollars by 2023, accounting for 67.13%. It is expected to reach 614 million US dollars by 2030, with a compound annual growth rate (CAGR) of 7.01% from 2023 to 2030.

Source: Research and compilation by DIResearch, 2023

Introduction to Major Manufacturers in the Chinese Rice Husk Ash Silica Market

Anhui Evosil Nanomaterials Technology Co., Ltd. was founded in 2018 and is located in the Economic and Technological Development Zone of Fuyang City, Anhui Province. It is a high-tech enterprise specializing in the research and development, production, and sales of bio based silica new materials technology. The company has established the world's first 10000 tons/year demonstration production line for the preparation of bio based silica by carbon dioxide acidification method, and plans to invest in the construction of a 90000 tons/year production line for the preparation of bio based silica by carbon dioxide acidification method. The company has passed management system certifications such as ISO9001, ISO14001, ISO45001, etc; And has passed multiple authoritative certifications in the automotive industry, including IATF16949 certification, ISO14067 (LCA full lifecycle), ISCC certification (International Sustainability and Carbon Certification), RCS certification, etc.

Related News

Rice husk white carbon black: Opportunities and Innovations from Rice By-products